SED is a revolutionary new technology of sewage treatment technology provided by Jiangsu Huanchuan Environmental Engineering Co., Ltd. to the global sewage treatment industry.

SED is a biochemical technology developed by the environmental research team of the University of Waterloo in Canada and Schutch in Germany, and supported by the technology platform provided by Huan Chuan Environment, which provides municipal sewage and industrial wastewater treatment plants and facilities around the world.

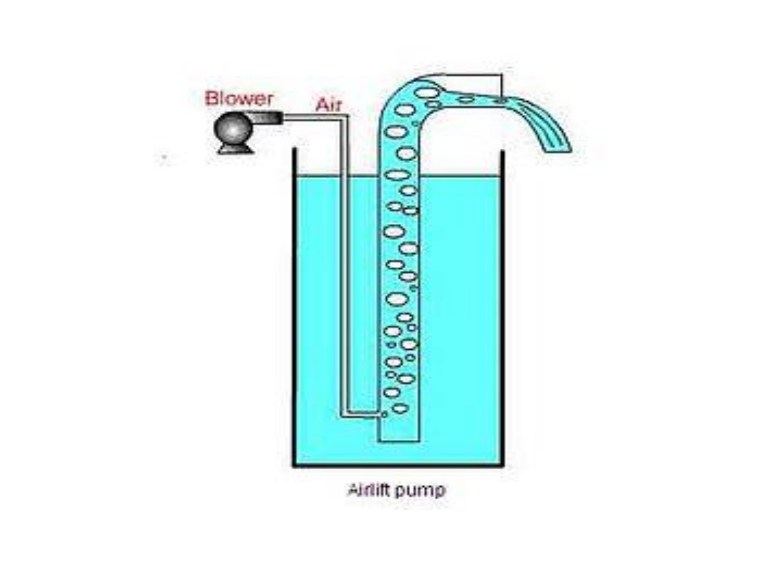

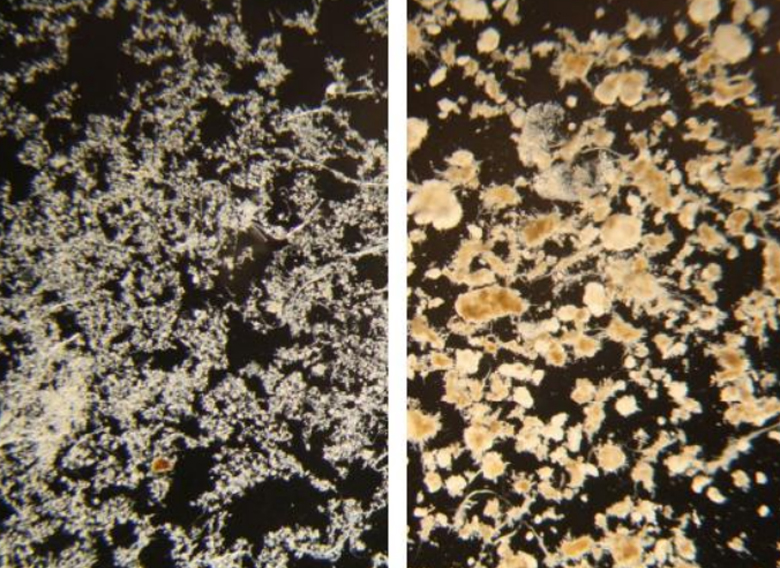

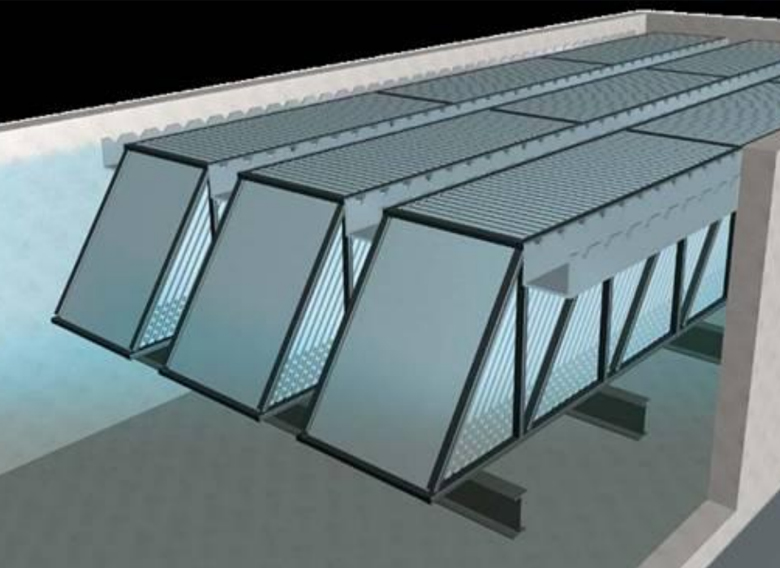

SED is a BioTAS micromixed hose aeration technology, BioFerm sludge fermentation to produce carbon source technology, BioAir air lift technology, BioDens microbial screening technology, BioHSS rapid clarification technology, anaerobic selective pool rich phosphorus bacteria (PAO) technology, Simultaneous nitrification, denitrification, nitrogen removal and biological phosphorus removal (SND and EBPR) technology and low dissolved oxygen aerobic pool 7 core patent technology combined into an integrated biochemical system process.

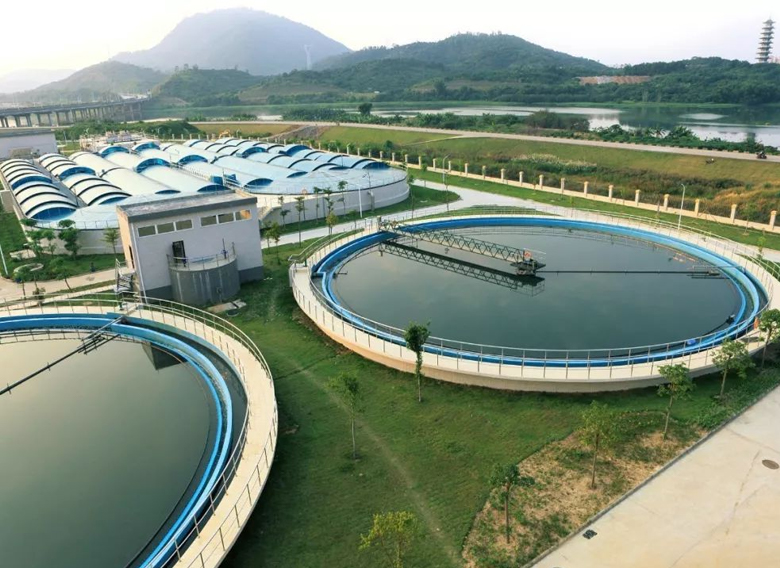

SED has been successfully applied and achieved remarkable results in dozens of sewage treatment projects in America, Europe and China, mainly covering municipal sewage, industrial parks, paper printing and dyeing, petrochemical, food and medicine and other sewage treatment fields. Dr. Imre Takacs, GLOBAL CEO of Dynamita Wastewater Simulation Company, and Dr. Dwight Houweling, Technical Director of North America, conducted quantitative simulation comparison analysis between SED and traditional biochemical technology. Compared with traditional biochemical technique, SED technique is proved to be advanced after simulation analysis, and a simulation analysis report is issued.

SED is very suitable for the upgrading and construction of municipal sewage and industrial wastewater treatment plants, and completely solves the problem of stable discharge of sewage treatment system up to standard.