Fangchenggang Steel Base project of Guangxi Iron and Steel Group Co., LTD

In April 2020, our company successfully won the bid of Fangchenggang Iron and Steel Base project (phase I) of Guangxi Iron and Steel Group Co., LTD. In this project, the rubber micro-porous tubular aerator HMT-65-1000-FlexSIL ® is selected, and the enhanced aeration system is adopted, which lays a foundation for the replacement and maintenance without production stop and water shutdown in the future.

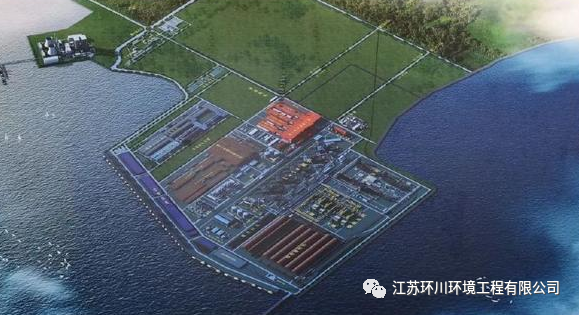

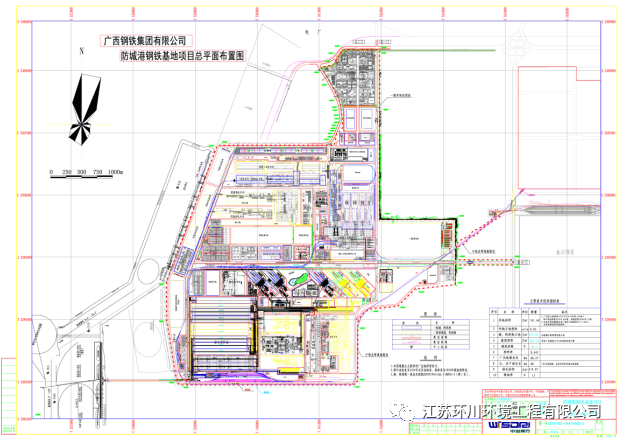

Guangxi Fangcheng Port planning map

The Fangchenggang Iron and Steel Base project (phase I) is another important milestone in the history of guangxi's industrial development, and a significant achievement of Fangchenggang city earnestly implementing the layout of the iron and steel industry and actively participating in the second venture of the metallurgical industry in the whole region. The total investment of the project is 36 billion yuan (excluding the investment before the restructuring), and the production scale of iron 8.5 million tons and crude steel 9.2 million tons will be formed upon completion.

Master plan design drawing

The wastewater treatment station belongs to the coking plant, which is a phase I construction project. It is used to treat the coking wastewater produced by the coking oven, dry quenching and gas purification devices in the coking plant, with a daily treatment capacity of 3120m²/ day. After the completion of the project, the aeration system is evenly aerated, and the air flow rate is 5m²/h per set. The effluent COD is ≤300mg/L and ammonia nitrogen is ≤1mg/L.

Field diagram of enhanced aeration system

Project Product Information

The FLEXSIL® diaphragm tube aerator HMT-65-1000 from OTT, Germany was selected for the project. FLEXSIL® is our recommendation for membrane use in demanding wastewater and ventilation systems designed for high efficiency and long life. These membranes can be used in thousands of deep basins, in highly polluted wastewater or at temperatures as high as 1000 ° C. The material does not harden and is resistant to various chemicals and oils.

FLEXSIL® diaphragm is available for MAGNUM® film tubular aerators and STANDARD2 tubular aerators.

MAGNUM ® is an integrated injection-molded product made from environmentally recyclable polypropylene (PP).

STANDARD2 tubular aerator is a tubular aerator for existing equipment to ensure air distribution along the entire length and strong film fit.

OTT's high-quality aeration hole can achieve aeration effect and stable and uniform aeration performance in application. We have achieved remarkable results in this respect, as evidenced by neutral efficiency measurements. The aeration hole can meet the specific design requirements related to different facilities.