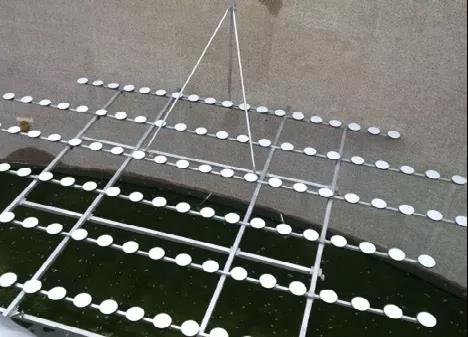

Comparison of diaphragm performance of OTT aerator

Material performance and applicable working conditions

OTT d-Rex disk and MAGNUM tubular diaphragm materials are mainly divided into rubber film and silicon rubber film. The two materials of aerator diaphragm are different in product performance and application conditions.

OTTFLEXNORM Rubber film:

A copolymer of ethylene, propylene, and a small amount of unconjugated diolefin, a type of ethylene propylene rubber.

1. Performance advantages

The material is cost-effective.

2. Performance disadvantages

In fat and aromatic solvents (such as gasoline, benzene, etc.) and mineral oil stability is poor, natural aging speed. Short service life, late easy to lead to diaphragm blockage, high energy consumption, excessive pressure caused by the fan jump stop. High temperature resistance is poor, it will accelerate aging, especially when the temperature exceeds 60℃.

3. Applicable working conditions

It is applied to small and medium-sized municipal sewage, and performs poorly in industrial sewage with complex water quality. Generally, the service life of municipal sewage is about 5 years, and the initial investment cost is slightly lower in projects with production stop, empting and replacement conditions on site.

OTTFLEXSIL silicone membrane: As a slightly more expensive rubber material, the main chain consists of alternating silicon and oxygen atoms

1. Performance advantages

Si-o-si bond is very stable to oxygen, ozone and ultraviolet light, without any additives, it has excellent weather resistance. At the same time has good oil resistance and chemical reagents and high and low temperature resistance. After the biofilm is attached, it can be used for conventional large gas scouring and pickling maintenance, with long service life and stable oxygen utilization rate.

2. Performance disadvantages

The physical and mechanical properties of silicone rubber are slightly weaker than that of general rubber. Under strong alkaline conditions, the properties change and the cost is slightly higher than that of rubber material.

3. Applicable working conditions

It is suitable for large municipal sewage and all kinds of industrial waste water with high requirements on product stability and energy saving performance, high temperature conditions, municipal sewage containing mixed industrial sewage sources, without production stop, discharge or underground sewage treatment plant conditions. Resistance and energy consumption performance is excellent. General municipal sewage service life of 10-12 years.

To sum up:

OTT's FLEXSIL silicone diaphragm provides enhanced resistance to aging, with little change in membrane resistance for municipal wastewater after 10 years and no significant deterioration in membrane performance for industrial wastewater after 5 years. For large sewage treatment plants, compared with EPDM products, it can save hundreds of consumption for enterprises every year.

Under various conditions, silicone aerated products can achieve better results than rubber products, especially in large municipal sewage, industrial waste water is widely used, its performance is far better than rubber aerated film material in terms of stable product life, blockage resistance, energy saving and consumption reduction, operation and maintenance.