Selection of microporous aerator

According to the size of the diffusion bubble, the aerator can be divided into three kinds: big bubble (φ in 15mm), medium bubble (φ between 2 ~ 6mm), micro bubble (φ is 1.5mm below). Microbubble aerator, also known as microporous aerator, has excellent oxygen filling performance, high oxygen utilization rate and dynamic efficiency, good mixing and stirring effect.

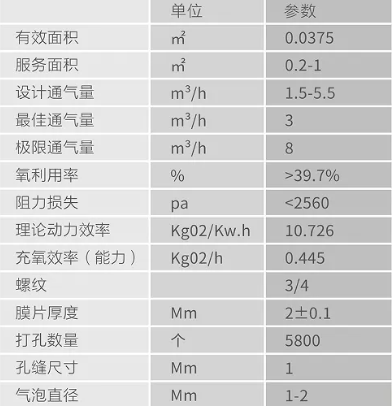

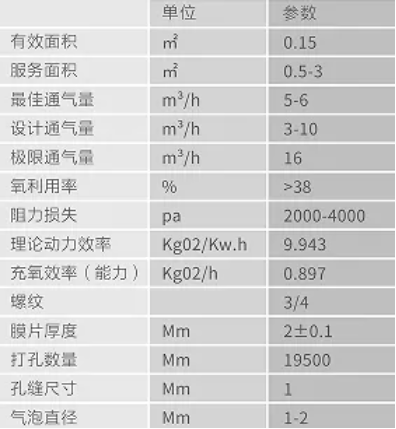

At present, the microporous aerator commonly used in China can be divided into ceramic (corundum), rubber diaphragm and silicone rubber aerator according to different materials. According to the structure can be divided into: plate type, disc type and tube type aerator. Plate aerator is seldom used in China. The main use of disc and tube type two. The technical performance of aerators with different materials and structures varies greatly.

First, the problems encountered in the practical application of microporous aerator

1. The microporous aeration diaphragm is torn and the problem of aeration tube surge occurs

Because part of aerated diaphragm is made of waste rubber, the tear strength of the diaphragm is affected by poor material quality. Combined with long-term exposure to sewage, the harmful ingredients accelerate the aging of the diaphragm. Therefore, under normal service pressure, the aerator and aeration diaphragm are easy to be torn, resulting in the problem of aeration tube surge.

2. The microporous aerator is blocked with uneven aeration in some areas

With the increase of use time, various aerators will appear different degrees of blockage, serious will cause uneven regional aeration.

3. With the increase of service time, the loss of aeration resistance increases gradually

Once the microporous aerator is blocked; It will lead to the increase of aeration system pressure and aeration resistance loss.

4. Inconvenient maintenance and management, difficult maintenance

Some microporous aerators adopt bottom aeration, which requires empting sewage and removing sludge for maintenance of underwater equipment. Installation, disassembly and cleaning are more cumbersome, large workload, high cost; It also affects the normal production operation.

Two, performance parameters and selection

The temperature of compressed air is allowed up to 120°C at the transfer point on the upper edge of the pool. Efficient exhaust characteristics throughout the loading range, with good durability, UV stability. Quick installation and long service life.

1. D - REX ® diaphragm

2. D - REX ® carrier

3 D - REX ® retainer ring

4. D-rex ® double thread fitting

The tubular aerator is a microporous diaphragm mounted on the aerator pipe, which is connected to the air supply branch pipe and diffuses into the water through the microholes in the diaphragm. Its integrated structure allows the air passage to be mounted on the underside of the support for uniform distribution, whereas other aeration equipment produced by companies only has many air intakes. All components are formic resistant. The MAGNUM ® aerator stand also solves buoyancy problems with its flow chamber.

MAGNUM® tube aerator uses a unique support tube and air distribution layer, integrated with AirRex® aeration equipment. Compressed air diffuses into the water between the support tube and the air distribution layer through the pores in the air distribution layer. It has the characteristics of 360 degree aeration diffusion, good oxygenation performance, good mixing and agitation.

1. Mounting head for cover nut

2. MAGNUM® hood nut, torque 25 Nm

3. O-ring for closed cover nut

4. MAGNUM® for AirRex®

5. Screw into the sleeve, torque 30Nm

6. Torque wrench

7. Insert sleeve for screwing into sleeve

8. Screw into the O-ring above the sleeve

9. Screw into the O-ring under the sleeve

3. Due to the brittle air distribution layer and rough surface structure of the ceramic and corundum aerators, it is easy to have uneven aeration, coagulated colloidal material and pore scaling in the interstices; Pressure loss increases sharply after a period of operation. Because the air distribution layer has no automatic closing function, it can not effectively prevent muddy water from entering the aerator, so the gap aeration will accelerate the blockage and scaling of the aerator.

Third, summary

From the current use, silicone rubber tube microporous aerator is an efficient and energy-saving aerator, good aeration performance, stable chemical performance, good mixing effect, small resistance loss; It is suitable for municipal wastewater, chemical, pharmaceutical, petroleum and other industrial wastewater.